Contents:

Managing supply chain risk is critical for any company. But why, you may ask. What kinds of risks should be managed? Read on and find out everything you need to know about supply chain risk management.

What Is Supply Chain Risk Management (SCRM)?

Supply Chain Risk Management (SCRM) is a systematic approach to identifying and evaluating both everyday and exceptional exposures, risks, and vulnerabilities throughout a company’s supply chain and developing mitigation strategies to overcome those threats and ensure business continuity.

Modern supply chains are frequently complex, with many moving components, and each step of your production process can have an impact on your company’s performance and success.

With so many stages and suppliers, disruptions and vulnerabilities can happen at any time. In order to prevent them and maintain your company’s performance, compliance, and brand image, risks must be assessed, monitored, and controlled. Here’s where supply chain risk management comes into play.

This level of monitoring may appear excessive at first. You might think that your vendors and service providers must have their own risk management programs implemented. And that’s probably true.

However, those risk management policies were created with the goals and needs of those businesses in mind, and they may not be compatible with your own requirements. Furthermore, having backup plans in case your supply chain is disrupted constitutes a significant factor in your supplier relationships.

Supply chain risk management can be handled using conventional methods such as spreadsheets, but many businesses are increasingly choosing supply chain management software systems (SCM software) to help with supply chain planning. As I mentioned before, the supply chain management process is a complex undertaking with numerous moving components, therefore having a unified source of information can aid in keeping your actions structured and accessible.

Before delving into the significance of supply chain risk management, let’s take a quick look at the risks that can disrupt a company’s supply chain. There are two types: internal and external.

External supply chain risks

These supply chain risks, as the name suggests, originate from outside of your company. Alas, this makes them more difficult to anticipate and necessitates more resources to overcome. Some examples are:

- demand risks – caused by unpredictable or misunderstood customer or end-customer demand

- supply risks – they happen when the raw materials, parts, or finished goods on which your company relies aren’t delivered on time or ever, interrupting the product flow.

- environmental risks – these come from outside the supply chain and are typically associated with economic, social, governmental, and climate factors (earthquakes, hurricanes, and tornadoes).

- business risks – these happen whenever one of the organizations you rely on to keep your supply chain running efficiently experiences sudden changes, such as the purchase or sale of a supplier company.

Internal supply chain risks

These supply chain risk aspects are under your control and can be observed and monitored through supply chain risk assessment technology, powerful analytics programs, IoT capabilities, and other tools. Even though internal supply chain risks are more controllable than external ones, they are still inevitable. Some of them are:

- Manufacturing risks – these are caused by disruptions of operations or processes within an organization.

- Business risks – happen due to disruptions in standard personnel, management, reporting, and other critical business operations.

- Planning and control risks stem from erroneous predicting and evaluations, as well as badly planned manufacturing and management.

- Remediation and contingency risks can arise if your company does not have a plan in place to deal with supply chain disruptions.

Why Is Supply Chain Risk Management Important for Businesses?

As it consists of numerous and diverse operations, the supply chain is critical for organizations of any size. It involves the transformation of natural resources, raw materials, and work-in-progress resources into a final good or service that is then offered to end customers. If one operation fails to deliver what is needed for the next stage in the supply chain on time, the entire supply chain can be disrupted. It only takes one minor error or delay to bring your business to a halt, resulting in lost revenues and significant harm to your brand image.

As businesses around the world strive to become more efficient, supply chains have become highly vulnerable to risks.

An exhaustive SCRM strategy is essential for organizations to be resilient and responsive in order to reduce supply chain risk. This entails handling all types of risk at all levels of the supply chain, including suppliers, logistics, locations, and more. Supply chain risk management will have a considerable competitive advantage in your industry if it is implemented correctly.

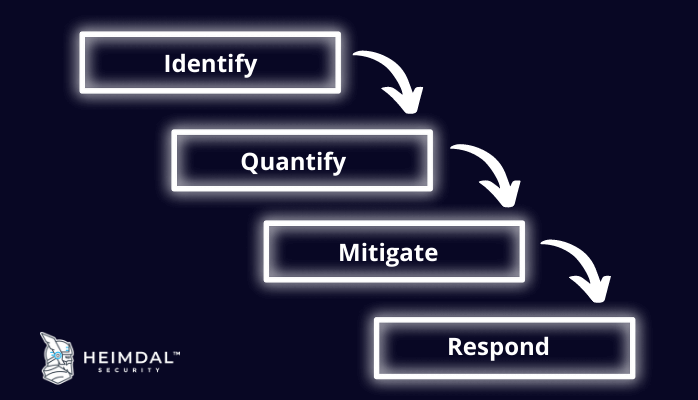

The stages of the supply chain risk management process that help organizations to understand and mitigate potential threats are:

- Identify. List which risks might have an impact on your supply chain, as well as where they might be found.

- Quantify. Evaluate the potential operational, economic, and reputational impact of these risks on your company.

- Mitigate. Create or identify appropriate strategies and tactics to mitigate the consequences of specific types of supply chain disruption.

- Respond. Determine how fast you can react to a disruption and how long it will take your organization to recover.

Supply Chain Risk Management Benefits

A supply chain risk management solution has numerous advantages, including:

Increased protection

Increased security and safety for you and your clients are one of the most obvious advantages of an SCRM system. You’ll be able to detect weaknesses before they become threats and respond faster to potential problems if you constantly monitor your supply chain.

Improves and Maintains Customer Satisfaction

A supply chain that is properly managed can help your customers have a pleasant experience. Regardless of your sector, keeping up with client demand and meeting customer obligations will be top priorities. Supply chain risk management ensures that your existing customers are satisfied by providing a smooth and consistent service.

Competitive Advantage

The good reputation you gain as a result of having a safe supply chain can give you a significant competitive advantage. SCRM will simplify and optimize your business operations and help you offer qualitative services.

Ability to Quickly Respond to Unexpected Events

Risk management can help you simplify an issue and even prevent it from occurring. It starts with the identification of the risks that might prevent you from delivering your products on time, determining what impact each risk would have on your operations, and devising quick solutions to deal with the problem.

Maintain Business Continuity

Risks differ from one company to another, however by considering the worst-case scenario for each situation, solutions can be identified if they will actually happen. That way, even if risks occur, you can keep your operations running smoothly without panicking.

Save Both Time and Money

Mitigating supply chain risks is an important job that takes a lot of time, hard work, and cooperation from employees and supply chain partners. A supply chain risk management program relieves you of some of the burdens, saving you time and money.

Protect Your Revenue and Image

Supply chain risk management (SCRM) will help you identify, evaluate, and monitor risks, as well as take proactive measures to avoid potential dangers from causing incidents, thus safeguarding your organization from financial and reputational harm.

Help You Stay Away from Legal Fines and Penalties

Fines, sanctions, and even imprisonment can be imposed for breaking laws and regulations. And, as supply chain standards tighten, prosecutions and financial penalties are increasing. Therefore, it’s more important than ever to protect your organization from legal liabilities, and a supply chain risk management program can help you ensure and demonstrate compliance.

SCRM Best Practices

- Automate operations that are involved in supplier risk management (SRM) to gather, evaluate, and control supplier information.

- Include details on supplier performance in your assessment to gain an accurate and deep understanding of possible financial issues.

- Recognize red flags that could indicate an issue and employ software to automate the process of detecting them early.

- Combine SCRM programs with procurement and supply chain management (SCM) software tools, such as spend visibility, e-sourcing, purchase-to-pay, contract management, and compliance technology.

- In order to give the executive team access to real-time observations of risk factors, create dashboards that continuously monitor and notify on supply risk metrics.

Conclusion

Understanding supply risks is more important than ever before as it allows purchasing businesses to respond to those threats effectively. Risk management should be a part of any goods procurement and supply practice. It is essential that organizations tackle the appropriate risks and employ the proper strategies.

Alternatively, follow us on LinkedIn, Twitter, Facebook, Youtube, and Instagram for more cybersecurity news and topics.

Network Security

Network Security

Vulnerability Management

Vulnerability Management

Privileged Access Management

Privileged Access Management  Endpoint Security

Endpoint Security

Threat Hunting

Threat Hunting

Unified Endpoint Management

Unified Endpoint Management

Email & Collaboration Security

Email & Collaboration Security